Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with CNC Egy!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

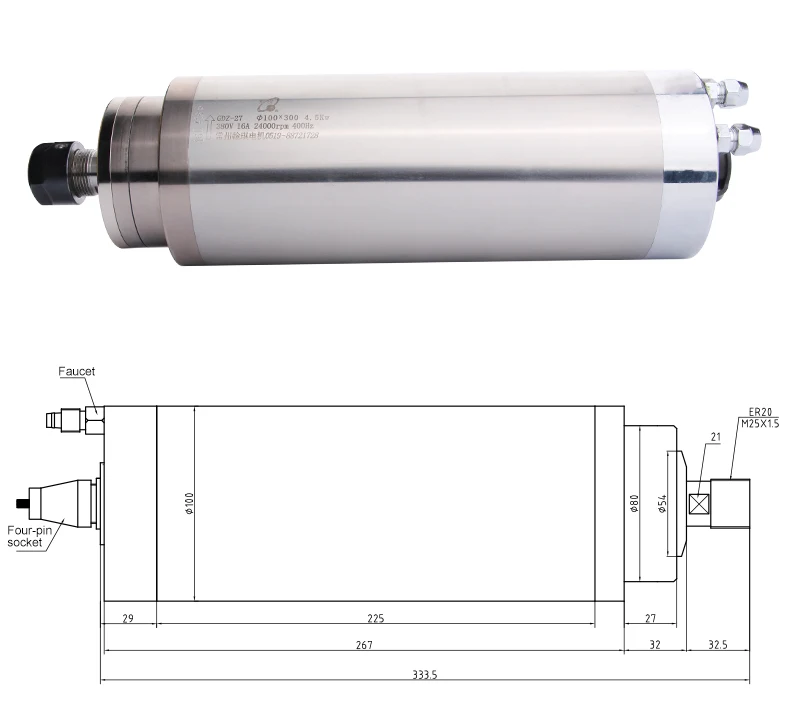

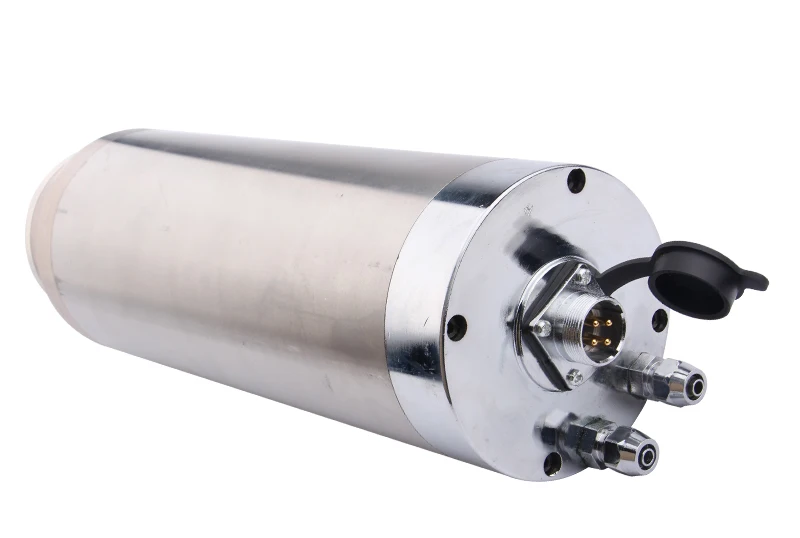

4.5KW --220V-- HQD Water Cooling Spindle

Size: 100x300mm (diameter of middle body: 100mm x length: 300mm)

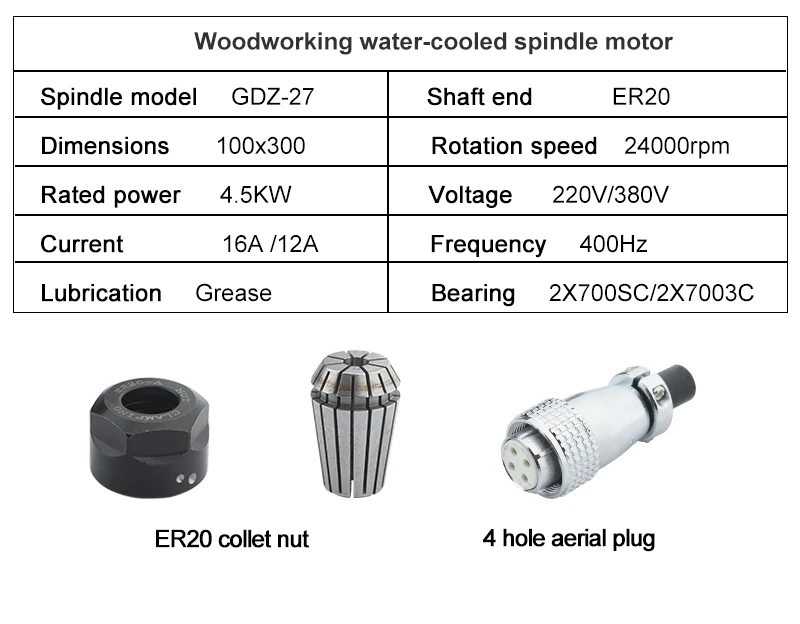

Speed regulation mode: The spindle speed can be changed by three-phase output inverter and adjusting the frequency of the inverter.

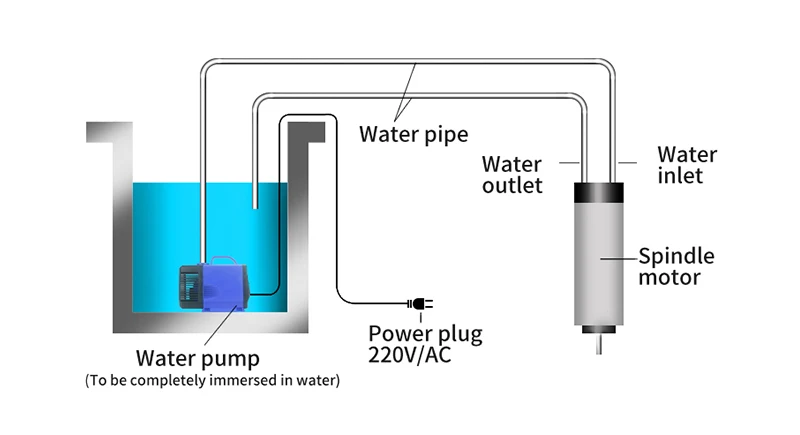

Cooling method: water cooling

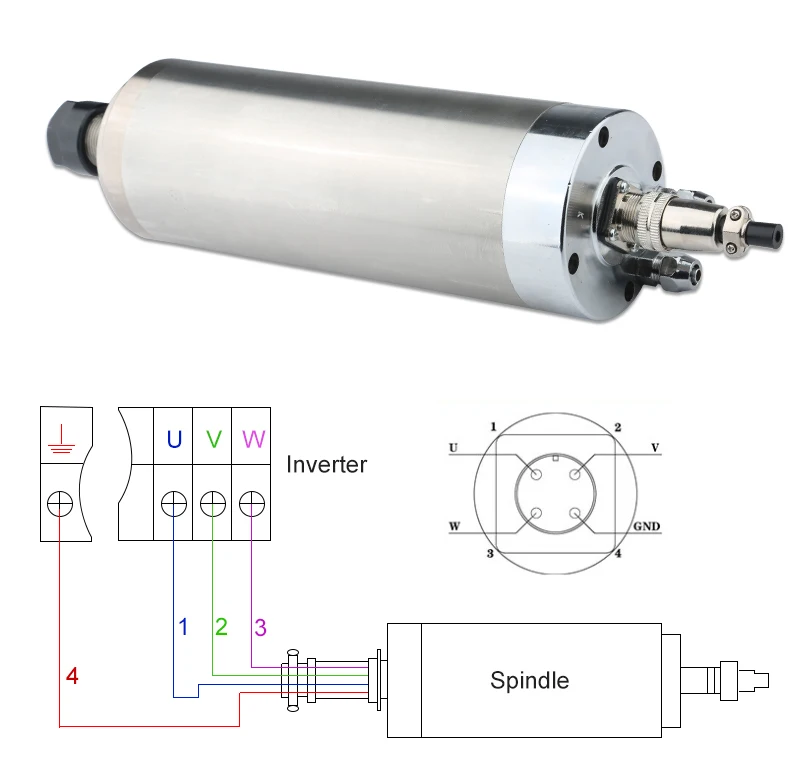

Power interface: Optional H20-4 pin waterproof air plug. The air plugs labeled "1", "2", "3", "4", "1", "2", "3" are connected to the inverter (U, V, W), 4 are connected to the inverter The device is grounded.

Power: 4.5kw

Voltage: 220V 380V

Current: 12A/16A

Frequency: 0-400Hz

Speed: 0-24000rpm

Runout: less than 0.01mm

Diameter (mm): 100

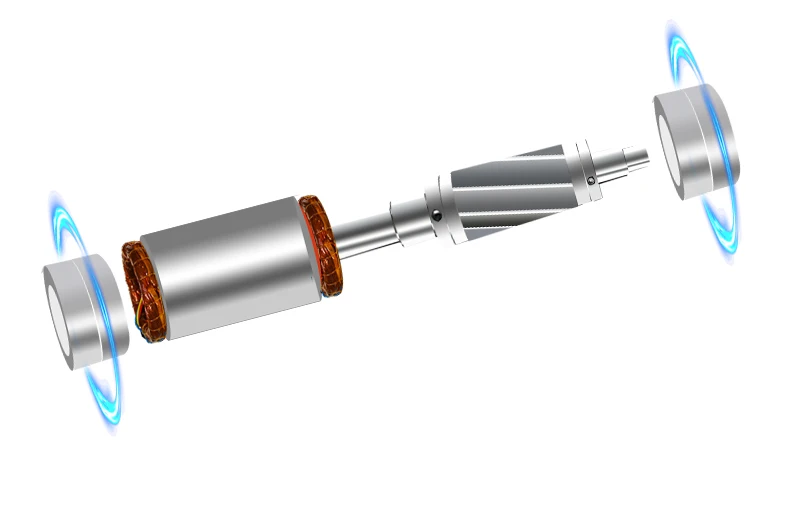

4 fully sealed angular contact bearings

Chuck: ER20

Grease lubrication

Main purpose: used for wood, bamboo, ordinary PCB, PVC, PMMA, plastic, bamboo, two-color board (ABS) and other non-metallic carvings.

●The working environment temperature of the spindle is usually -10~40.

●Before installing the first electric spindle to rotate the spindle head by hand, you should feel flexibility and no blockage.

P4 fully sealed angular joint bearings can extend the life of the spindle.

The longer the length, the greater the torque and the greater the power.

Careful assembly makes the spindle more precise.

The accuracy is 0.01mm, and the coaxial cable is less than 0.0025mm

1. Our main shaft uses 4 bearings.

2. Bearings are resistant to high temperature and low heat

3. The ball bearing has low friction, low noise and long service life.

●When the spindle is stored and transported, the bearing condition inside the high-speed grease will change, and the customer should run it at low speed for 30 minutes. Then increase slowly at a speed of 3000 rpm, running for 20 minutes each time . The spindle and inverter should work together. The specifications and parameter settings of the inverter match the spindle parameters.

●To connect the inverter main shaft, the three-phase inverter power cord should be welded to the plug 1 (U), 2 (V), 3 (W) pin, and the grounded pin 4. After turning on the power, observe whether the spindle rotation axis always shows the direction. If it is inconsistent, turn it off immediately, and replace the two wires of the three-phase power supply connected to the inverter and the spindle.

●Before using the spindle every day, it must run at low speed for 15-20 minutes. Clamp the cutter on the spindle, the chuck nut, chuck, and cutter must be clean enough. The shank inserted into the chuck must be larger than 15mm.

●The water-cooled spindle must be used together with the water pump. Otherwise, the spindle will quickly break.

●The AC spindle motor must be used together with the inverter. The power of the inverter needs to be equal to or greater than the power of the spindle. Before use, please set the inverter parameters suitable for the spindle. Otherwise, the spindle and inverter will break immediately.

●When using the spindle, the noise is different from before, so please stop the spindle immediately. You need to replace the spindle bearing.

●The water-cooled spindle must be used together with the water pump. Otherwise, the spindle will quickly break.

●The AC spindle motor must be used together with the inverter. The power of the inverter needs to be equal to or greater than the power of the spindle. Before use, please set the inverter parameters suitable for the spindle. Otherwise, the spindle and inverter will break immediately.

●When using the spindle, the noise is different from before, so please stop the spindle immediately. You need to replace the spindle bearing.

-18x16.jpg)